LED controls let plants grow

Issue 02-2015:

read all articles online

read as pdf

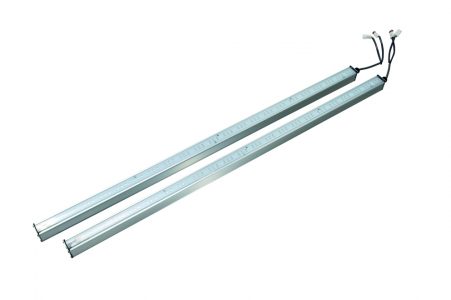

Rohm’s EnOcean-based solution was integrated into the wireless control system of Ushio Lighting’s LED strips, which were applied in vegetable factories solely operating with artificial light. About 10,000 LED strips were already put into operation in the factory.

EnOcean transmitter module (TCM 410J) implemented inside the LED strips. Microcomputer with dimming control signal output function by Lapis Semiconductor (lower right).

In recent years, vegetable factories have gotten lots of attention due to their stable crop yield and the possibility of avoiding agrochemicals. Until now, in most vegetable factories, the control of dimming functions or the scheduled on/off switching of the LED strips was either not supported or is realized by line-powered applications.

Limits of wires

There are many different plants, which do not all grow under the same light conditions. However, the flexible adaption of the available line-powered control systems would have been too complicated due to the need for many cables. Furthermore, the precise setting and control of the lights, depending on the vegetables’ growth stage, costs lots of time and money.

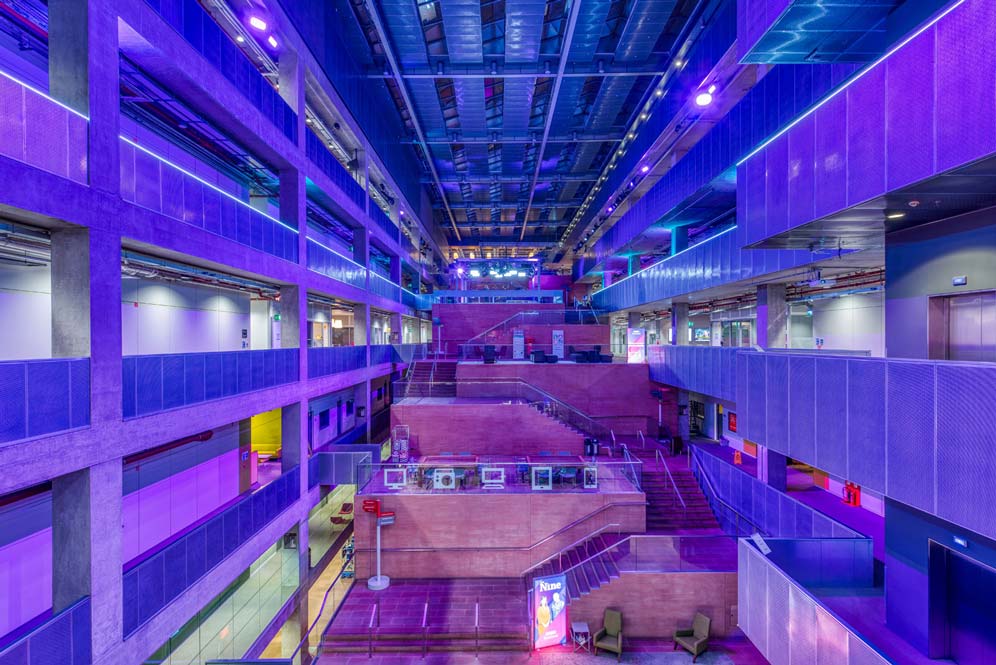

Nihon Yamamura Glass Co., Ltd. vegetable factory in Hyogo Amagasaki

Demand for wireless solution

Therefore, the market strongly demanded a wireless system to control dimming and timing functions of LED lights. Ushio Lighting responded to this market demand by combining their know-how in LED radiation, the implementation of LED components and optical planning with EnOcean wireless technology provided by Rohm. The result is a wireless control system for LED vegetable grow lights, which is already available on the market.

Control in real time

In vegetable factories, over 10,000 LED strips need to be controlled simultaneously and in real time. There are many standards for wireless communication such as Wi-Fi or Zigbee. However, this time EnOcean technology was applied as it is the most advanced standard when it comes to simultaneous real time communication.

For the future, there are plans to add batteryless EnOcean sensors to this system for measuring temperature, light intensity or concentration of CO2, for example, for added value to the whole vegetable grow system. Currently, the wireless control system for LED grow lights is being further developed for other frequencies covering countries like China, the US and Europe.

A controller (PC) sends out a dimming signal to the EnOcean module (TCM 410J) inside every LED strip from Ushio Lighting. Responding to the received information, the Lapis Semiconductor Microcomputer passes the dimming signal on to the LED power supply and executes the dimming. The software provided for this system allows setting up a schedule to automatically control the LED dimming.

This system’s benefits at a glance

- Easy dimming and timing with wireless communication

- Reduction of an initial construction costs by easy and reduced wiring

- PC-based changes to layout or control patterns independent of the luminaires

- Integrated repeater functionality of the luminaires for the wireless communication (currently applying for a patent)

New articles in Smart Lighting

Top articles